-

Tri Clamp Compatible Fittings

- Tri Clamp Compatible X NPT Adapters

- Tri Clamp Compatible X Hose Barb Adapters

- Tri Clamp Compatible X Cam & Groove Adapters

- Tri Clamp Compatible X Quick Disconnect Adapters

- Tri Clamp Compatible X Beer Thread Adapters

- Tri Clamp Compatible X Garden Hose Thread adapters

- Tri Clamp Compatible X Corny Post Thread Adapter

- Tri Clamp Compatible X Compression Adapters

- Tri Clamp Compatible X Flare Adapters

- Tri Clamp Compatible X BSP Adapters

- Tri Clamp Compatible Clamps

- Tri Clamp Compatible Gaskets

- Tri Clamp Compatible Valves

- Tri Clamp Compatible Ferrules

- Tri Clamp Compatible Caps

- Tri Clamp Compatible Elbows

- Tri Clamp Compatible Tees

- Tri Clamp Compatible Wyes

- Tri Clamp Compatible Crosses

- Tri Clamp Compatible Sight Glasses

- Tri Camp Compatible Concentric Reducers

- Tri Clamp Compatible Eccentric Reducers

- Tri Clamp Compatible Cap-Style Reducers

- Tri Clamp Compatible Spools

- Tri Clamp Compatible Check Valves

- Tri Clamp Compatible PRV Tank Breathers

- Tri Clamp Compatible Pressure Gauges

-

Shop By Size

- 1/2"-3/4" Tri Clamp Compatible Fittings

- 1"/1.5" Tri Clamp Compatible Fittings

- 2" Tri Clamp Compatible Fittings

- 2.5" Tri Clamp Compatible Fittings

- 3" Tri Clamp Compatible Fittings

- 4" Tri Clover Compatible Fittings

- 6" Tri Clover Compatible Fittings

- 8" Tri Clover Compatible Fittings

- 10" Tri Clover Compatible Fittings

- 12" Tri Clover Compatible Fittings

- Brewery Controllers

- Brew Stands & Systems

- Brewing Kettles & Hop Filters

- Burners & Accessories

- Cam & Groove Fittings

- Carbonation Stones

- Conicals & Accessories

- CIP Spray Balls

- Custom Welding

- Fermentor Kits

-

Gaskets

- 1/2" & 3/4" Tri Clamp Compatible Gaskets

- 1"/1.5" Tri Clamp Compatible Gaskets

- 2" Tri Clamp Compatible Gaskets

- 2.5" Tri Clamp Compatible Gaskets

- 3" Tri Clamp Compatible Gaskets

- 4" Tri Clamp Compatible Gaskets

- 6" Tri Clamp Compatible Gaskets

- 8" Tri Clamp Compatible Gaskets

- 10" Tri Clamp Compatible Gaskets

- 12" Tri Clamp Compatible Gaskets

- Kegging Equipment/Accessories

- Modular Return System

- O-Rings

- Pumps

- Quick Disconnect Fittings

- RIMS Tubes & Electric Brewing

- Thermowells

- Stainless Tubing

- Threaded Fittings

- Temperature Probe Components

- Temperature Sensors

- Wort Strainers

- Tubing/Hose

- Weldless Fittings

- Merch

- Clearance

- Anvil Brewing

- Blichmann Engineering

- Five Star Chemicals

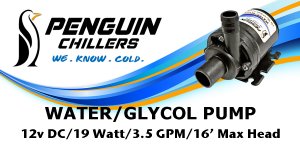

- Penguin Chillers

- Tapcooler Bottle Filler & Accessories

Penguin 1/2 HP Glycol Chiller

PENGUIN-GLYCOL-12HP

FREE SHIPPING (Continental 48 States)

Drop shipped directly from Penguin Chillers. Shipping times may vary and due to the size of the item it can take up to 3-4 weeks. For a more accurate timeframe please check with Penguin Chillers directly.

Because it is drop shipped, it cannot be expedited.

1/2HP Glycol Bath Chiller

2,500 BTU @ 28F

1 Year Standard Warranty

Proudly Built in the USA

Does not include a pump but can be purchased separately in the accessory package

Now offering Penguin Chillers! Penguin offers a great selection of glycol chillers that pair nicely with our line of conical fermentors and unitanks. Drop shipped directly from Penguin Chillers so if you have more items in your cart they will ship separately.

See attached PDF for full specifications from Penguin Chillers