-

Tri Clamp Compatible Fittings

- Tri Clamp Compatible X NPT Adapters

- Tri Clamp Compatible X Hose Barb Adapters

- Tri Clamp Compatible X Cam & Groove Adapters

- Tri Clamp Compatible X Quick Disconnect Adapters

- Tri Clamp Compatible X Beer Thread Adapters

- Tri Clamp Compatible X Garden Hose Thread adapters

- Tri Clamp Compatible X Corny Post Thread Adapter

- Tri Clamp Compatible X Compression Adapters

- Tri Clamp Compatible X Flare Adapters

- Tri Clamp Compatible X BSP Adapters

- Tri Clamp Compatible Clamps

- Tri Clamp Compatible Gaskets

- Tri Clamp Compatible Valves

- Tri Clamp Compatible Ferrules

- Tri Clamp Compatible Caps

- Tri Clamp Compatible Elbows

- Tri Clamp Compatible Tees

- Tri Clamp Compatible Wyes

- Tri Clamp Compatible Crosses

- Tri Clamp Compatible Sight Glasses

- Tri Camp Compatible Concentric Reducers

- Tri Clamp Compatible Eccentric Reducers

- Tri Clamp Compatible Cap-Style Reducers

- Tri Clamp Compatible Spools

- Tri Clamp Compatible Check Valves

- Tri Clamp Compatible PRV Tank Breathers

- Tri Clamp Compatible Pressure Gauges

-

Shop By Size

- 1/2"-3/4" Tri Clamp Compatible Fittings

- 1"/1.5" Tri Clamp Compatible Fittings

- 2" Tri Clamp Compatible Fittings

- 2.5" Tri Clamp Compatible Fittings

- 3" Tri Clamp Compatible Fittings

- 4" Tri Clover Compatible Fittings

- 6" Tri Clover Compatible Fittings

- 8" Tri Clover Compatible Fittings

- 10" Tri Clover Compatible Fittings

- 12" Tri Clover Compatible Fittings

- Brewery Controllers

- Brew Stands & Systems

- Brewing Kettles & Hop Filters

- Burners & Accessories

- Cam & Groove Fittings

- Carbonation Stones

- Conicals & Accessories

- CIP Spray Balls

- Custom Welding

- Fermentor Kits

-

Gaskets

- 1/2" & 3/4" Tri Clamp Compatible Gaskets

- 1"/1.5" Tri Clamp Compatible Gaskets

- 2" Tri Clamp Compatible Gaskets

- 2.5" Tri Clamp Compatible Gaskets

- 3" Tri Clamp Compatible Gaskets

- 4" Tri Clamp Compatible Gaskets

- 6" Tri Clamp Compatible Gaskets

- 8" Tri Clamp Compatible Gaskets

- 10" Tri Clamp Compatible Gaskets

- 12" Tri Clamp Compatible Gaskets

- Kegging Equipment/Accessories

- Modular Return System

- O-Rings

- Pumps

- Quick Disconnect Fittings

- RIMS Tubes & Electric Brewing

- Thermowells

- Stainless Tubing

- Threaded Fittings

- Temperature Probe Components

- Temperature Sensors

- Wort Strainers

- Tubing/Hose

- Weldless Fittings

- Merch

- Clearance

- Anvil Brewing

- Blichmann Engineering

- Five Star Chemicals

- Penguin Chillers

- Tapcooler Bottle Filler & Accessories

Choosing the Right Gasket Material

09 Oct 2020

A Tri Clover Compatible Clamp and Gasket along with a pair or Tri Clover fittings is required to make a complete connection. Gaskets come in a variety of materials and most of the time it comes down to personal preference. Some people prefer silicone for the flexibility and wide temperature range. Some people prefer the darker gaskets like EPDM and BUNA to hide discoloration. Let's go over each material we carry and it's unique properties so you can choose the best gasket for you.

SILICONE

Silicone is by far our most popular gasket material. These gaskets have a very wide temperature range of -58ºF to 446ºF making them suitable for a wide range of applications and great for home brewing locations where they will be near flame or in heat wash. They are very flexible and relatively soft making them easy to work with and seal. They can get gummy over time when used with strong acids and caustics in commercial applications. Silicone brewery gaskets are translucent clear.

- Temperature Range: -58ºF to 446ºF

- Physical Characteristics: Very flexible and soft

- Best For: Locations near a flame or heat wash

EPDM

EPDM brewery gaskets have a narrower temperature range than silicone (-30ºF to 300ºF) but stand up to stronger acids and caustics than silicone making them more desirable in commercial applications and excellent for home brewery applications. EPDM brewery gaskets are relatively soft, easy to seal and probably the best all around choice for any application that doesn't need to live close to a flame source. EPDM brewery gaskets are black and can help hide any discoloration that can happen over time.

EPDM brewery gaskets have a narrower temperature range than silicone (-30ºF to 300ºF) but stand up to stronger acids and caustics than silicone making them more desirable in commercial applications and excellent for home brewery applications. EPDM brewery gaskets are relatively soft, easy to seal and probably the best all around choice for any application that doesn't need to live close to a flame source. EPDM brewery gaskets are black and can help hide any discoloration that can happen over time.

- Temperature Range: -30ºF to 300ºF

- Physical Characteristics: Very flexible and soft

- Best For: Breweries using strong acids and caustics

PTFE TEFLON

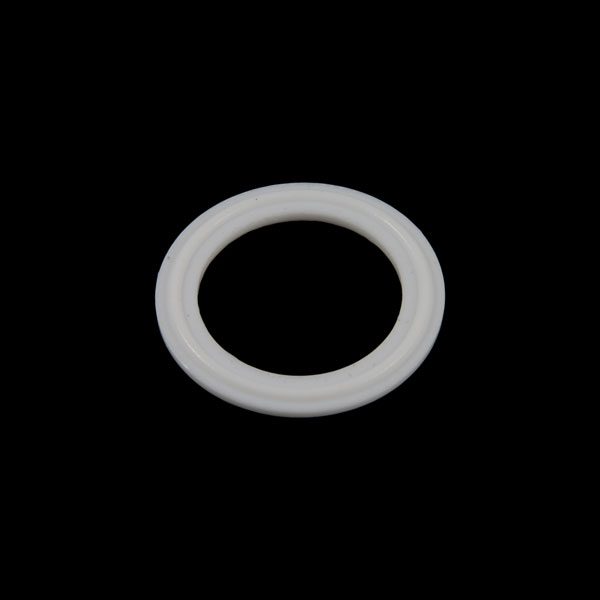

PTFE Teflon brewery gaskets have the widest temperature range (-100ºF to 500ºF) and are also the hardest making them ideal for locations that need to rotate against each other like racking arms. (Never rotate or loosen a connection that is holding back hot liquid!) Being hard, they are somewhat more difficult to get a good seal. PTFE brewery gaskets are solid white.

- Temperature Range: -100ºF to 500ºF

- Physical Characteristics: Very hard and rigid

- Best For: Locations needing to rotate

ENVELOPE (PTFE & EPDM)

These gaskets are a newer arrival and offer the best of both worlds between PTFE and EPDM. They offer the rigidity of PTFE to be used in locations that require rotating fittings, but also help provide a better seal with having the EPDM soft liner. A PTFE envelope gasket has the chemical resistance of PTFE and the elastomeric characteristics of EPDM.

- Temperature Range: -30ºF to 300ºF

- Physical Characteristics: Hard with some flexibility

- Best For: Locations needing to rotate and easier to get a better seal than straight PTFE

BUNA-N

BUNA-N brewery gaskets have a fairly narrow temperature range (-30ºF to 200ºF) but remain flexible across that range and seal well. They do not do well with acid (Star-San is fine) or caustic cleaners and should be kept away from UV light where they can oxidize. BUNA-N brewery gaskets are a good choice for the fermentation side of a brewery where their low cost makes them nearly disposable. Black in color.

- Temperature Range: -30ºF to 200ºF

- Physical Characteristics: Very soft and flexible

- Best For: Fermentation side

VITON

FKM (Generic for Viton) Tri Clover compatible gaskets offer the best performance against oils and fats while still maintaining good resistance to acids and alkalis. Can swell when in contact with Nitric, Formic and peracetic acids and weakened by strong caustic. Ideal for bio-diesel and other fuel applications but is not considered a food-safe product.

- Temperature Range: -25°F to 400°F

- Physical Characteristics: Very soft and flexible

- Best For: Bio-diesel and other fuel applications. Not food-safe.

Posted on Categories :

Gaskets,

Tri Clamp Compatible Gaskets

Comments